Nestled in the heart of small-town America stands a manufacturing powerhouse that embodies the spirit of American engineering. The Whirlpool Corporation’s Clyde, Ohio manufacturing facility isn’t just one of the largest washing machine factories in the world, it’s a testament to generational dedication, small-town values and engineering pride that translates into the dependability of the Maytag Commercial Laundry line.

A Legacy of Commercial Laundry Excellence

What makes Maytag Commercial Laundry machines exceptional? It starts with the people who build them. With an average tenure of 15 years for hourly employees and 14 years for salaried staff, expertise on the factory floor isn’t measured in months—it’s measured in decades.

“I’m a third-generation employee,” shares Sr. Analyst, Operations, Jason Alejandro. “My grandfather worked here for 40 years before he retired. My mother and stepfather both worked here for 40 years. They just retired last year, and I’m working on year 19.”

This generational knowledge isn’t just a point of pride, it’s a competitive advantage that directly benefits Maytag Commercial Laundry customers. Team members often witness the evolution of washing machine technology over decades—that expertise contributes to the reliability and performance of the products produced.

Manufacturing Precision Meets Performance

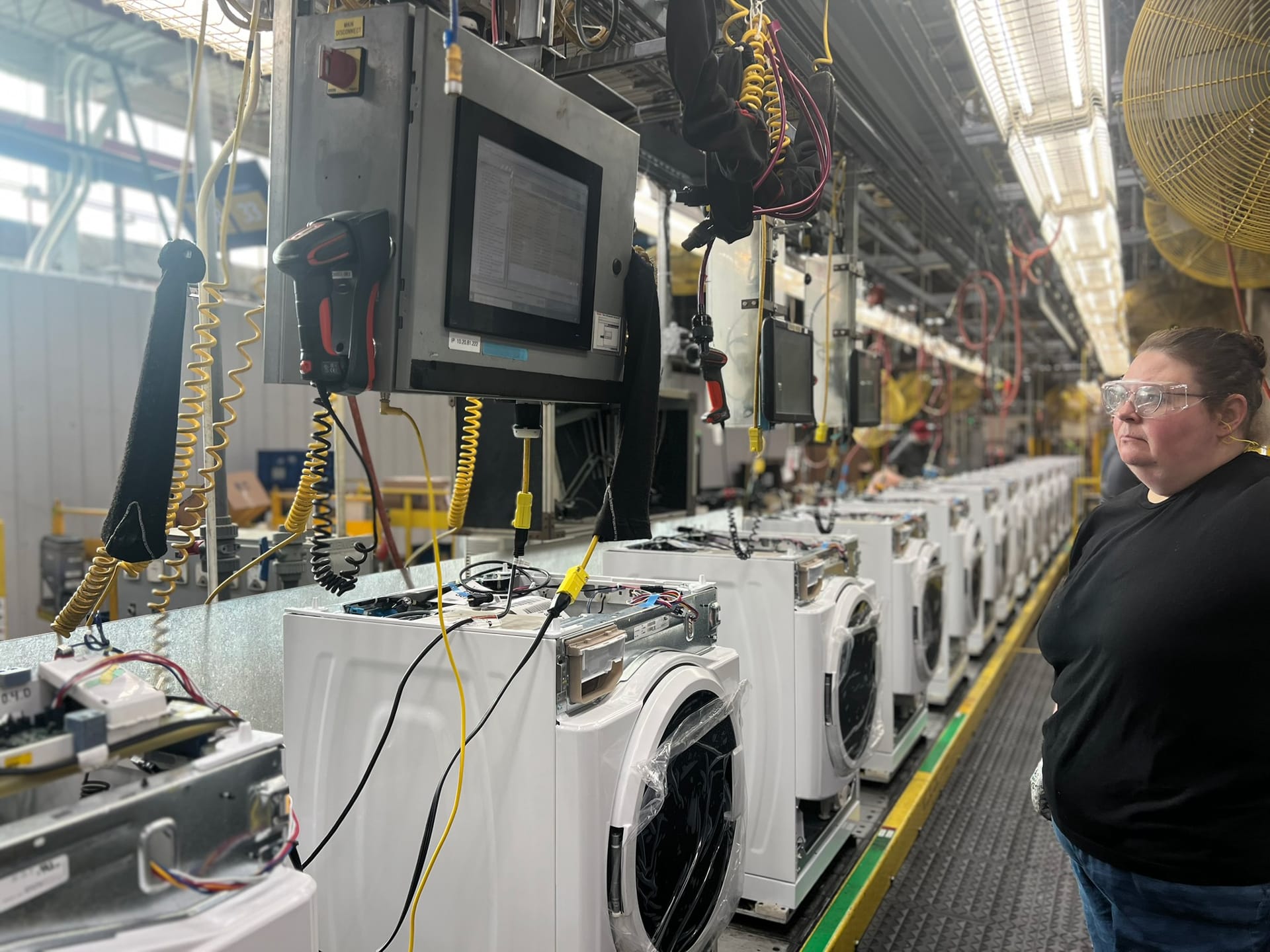

At the Clyde facility, the dedicated commercial laundry equipment line, which produces around 400 units daily, combines the resources of a large-scale manufacturing operation with a specialized focus on commercial-grade dependability and durability. As Clyde Plant Lead Ryan Deland explains, “it is its own unique value stream with dedicated processes and dedicated equipment,” ensuring the reliability expected of commercial-grade equipment.

Separating the commercial laundry line from the residential platforms was a strategic decision driven by practical considerations. The residential lines run at significantly higher volumes and speeds, while the commercial line manages greater intricacies, building machines for diverse global markets. This separation allows the line to manage rapid changeovers efficiently, despite this complexity. One unique aspect of the commercial line is the ability to produce both top-load and front-load commercial washers on the same line, which is uncommon in the industry.

Mike Carroll, Sr. Manager, Operations/Production, notes that the unique value stream of the commercial line also includes the people who operate it. “Most of our employees who work in commercial laundry are higher tenured. They tend to be more experienced assemblers who maybe cut their teeth on the high-speed production lines and then transferred their [shift] bid and seniority to the commercial laundry line.

Every Maytag Commercial Laundry machine manufactured at Clyde, is built for the rigors of commercial use. Dependable from the inside out.

Commercial Laundry Expertise

The Maytag Commercial Laundry line benefits from being operated in a facility with extensive manufacturing capabilities and institutional knowledge. This integration provides unique advantages as knowledge is shared across both the residential and commercial lines. “If I run into an issue on commercial drums, I’m pulling my residential drum expert into the equation to get the line running,” notes Mike Fought, Sr. Manager Quality.

This cross-pollination of expertise ensures that commercial laundry equipment benefits from the same engineering excellence that has made Maytag a trusted name for generations, while receiving the specialized attention commercial applications demand.

The Clyde facility continuously evolves its manufacturing processes to improve efficiency and outcomes. Advanced process controls have been implemented to eliminate potential failure modes. For example, automated systems now verify screws are properly torqued before allowing a machine to advance to the next production stage, building quality control directly into the manufacturing process.

American Engineering: Tested to Last

From start to finish, Maytag Commercial Laundry equipment is built for the demands of commercial use. This includes rigorous testing protocols. Each machine undergoes extensive evaluations and assessments to ensure durability, including prolonged testing durations to confirm reliability, higher sampling rates to verify consistent performance across multiple units and specialized scenarios to replicate real-world usage.

“We try to simulate situations you might see in a commercial environment by overloading the washing machine and other challenges you might not see as much on the residential side,” explains Fought.

Small Town USA, World-Class Manufacturing

The Clyde facility isn’t just a manufacturing plant, it’s the economic heartbeat of a community. As DeLand puts it: “It’s built here in a small community. And it’s what contributes to a vibrant community. It’s U.S. manufacturing. It’s small-town USA.”

This connection to community translates directly to the end-product. When neighbors depend on the success of what you build, there’s an added level of accountability and pride in craftsmanship that simply can’t be replicated elsewhere. According to DeLand, “Clyde Pride is the Spirit of Winning. It’s generational. It’s legacy bound. Building the best product we possibly can helps sustain our community and helps sustain our families.”

A Legacy of Excellence in Every Machine

Every Maytag Commercial Laundry machine is more than just a piece of equipment—it’s the result of generations of expertise, dedication and craftsmanship. Built with care and a deep commitment to deliver the reliability, efficiency and durability that commercial laundry customers depend on. That’s the Maytag Commercial Laundry difference. That’s Clyde Pride.